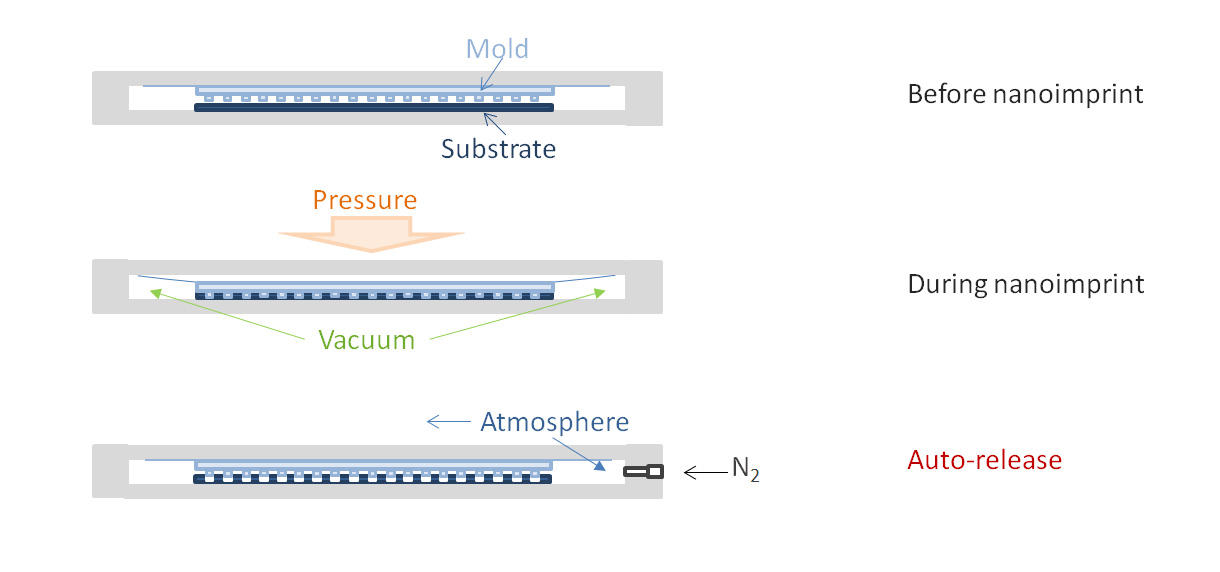

Mold/Substrate auto release

EZImprinting's unique, patented auto-release function allows the imprint mold automatically released from the imprinted substrate by adjusting the pressure inside and outside the nanoimprint chamber through the programmable controller. Auto-release function is as simple as pressing "next" on the controller but amazingly prevents mold and substrate damage during separation and maximizes imprint yield.

Soft/flexible substrate hybrid mold (Fusion Mold)

Recently, soft molds have become more and more popular due to their high production yield. Soft/flexible molds fall into two categories: single material molds and hybrid material molds.

Single material molds are easier to fabricate, but there are inherent trade-offs. Single material molds present a dilemma in balancing high yields with high resolution. Softer substrates increase effective yield, but cannot provide maximum resolution. Conversely, harder materials will offer increased resolution but lower overall yield.

Therefore hybrid material molds were developed. Hybrid material molds usually rely upon on a soft substrate such as PDMS. Some of them add a hard backing (i.e. glass) for easy operation; others add a rigid top layer to increase resolution; other alternatives add both backside support and a top layer.

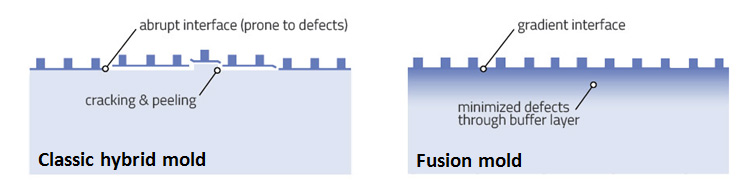

These hybrid material molds help to overcome the single material mold dilemma. However, thin layers of two different materials (with dissimilar expansion coefficients) bonded together can result in defects ("peeling off" and "cracking").

To overcome these problems, we have developed a special hybrid mold called the "fusion mold". Our fusion mold employs a buffer layer between the two dissimilar materials, alleviating the stress defects common in other hybrid molds. This buffer layer fuses in a gradient manner, allowing enhanced, defect-free bonding of the two materials.