PL Series

EZImprinting introduces a bench-top, stand-alone nanoimprint platform: The PL series PL200/400/600. This platform provides a mechanical stage with micro-positioning fixtures for mounting a nanoimprint chamber, UV-curing source, and alignment microscope. It functions both as a nanoimprint system and as a traditional mask aligner while providing programmable, automatic control of your entire imprinting process.

EZImprinting Advantages

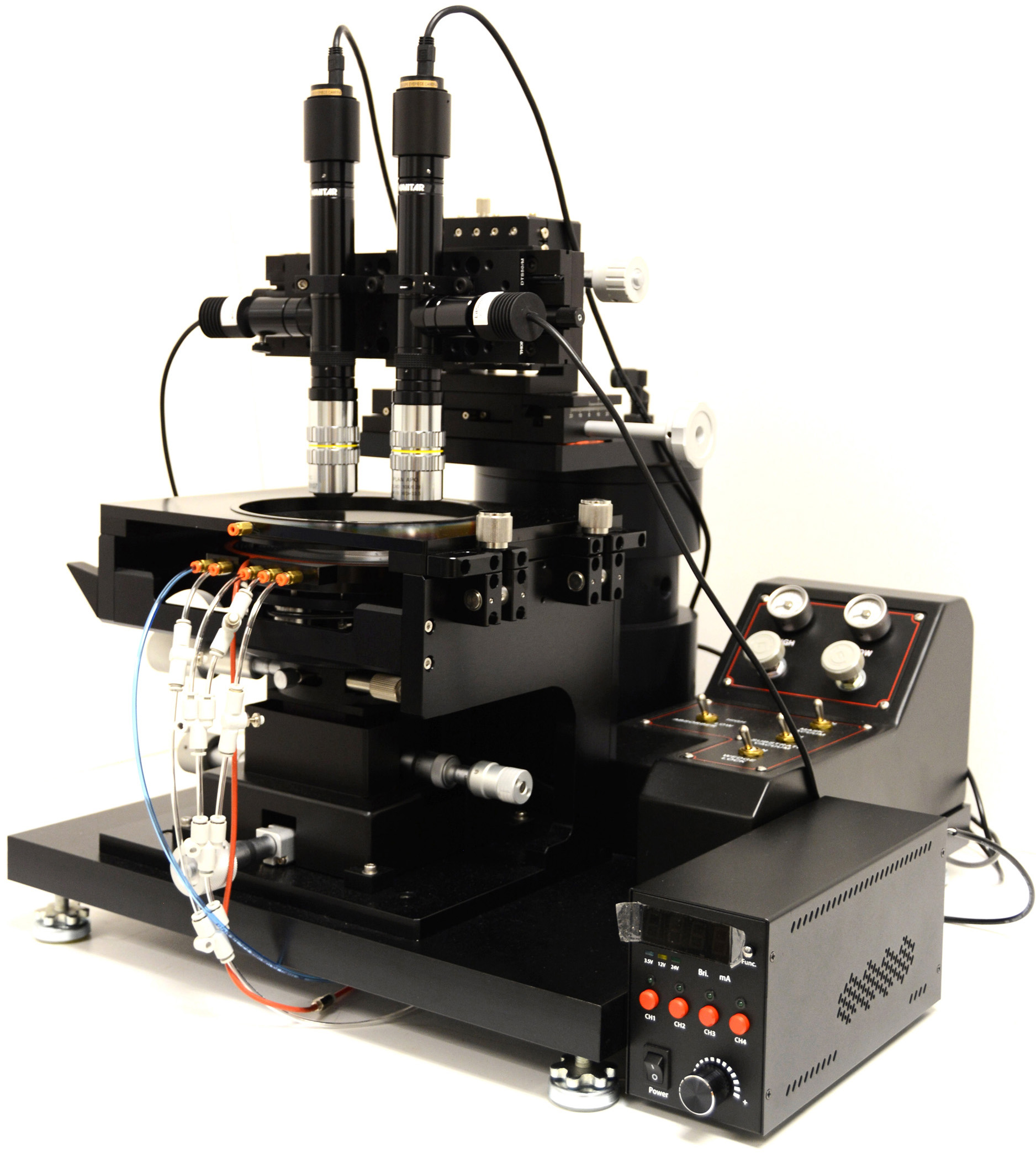

PL400 with alignment microscope

PL400 with alignment microscope

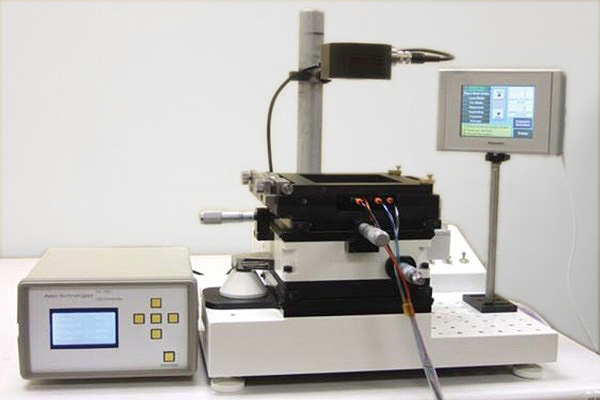

PL400 with UV LED source

PL400 with UV LED source

EZImprinting Process Specifications

| PL200 | PL400 | PL600 | |

|---|---|---|---|

| Substrate size | 2" standard (smaller sizes, irregular shapes compatible) | 4" standard (smaller sizes, irregular shapes compatible) | 6" standard (smaller sizes, irregular shapes compatible) |

| Imprint area | Same as wafer size | Same as wafer size | Same as wafer size |

| Mold plate size | 2" and 1" | 4", 2" and 1" | 6", 4", 2" and 1" |

| Imprint pressure | 1 psi standard | ||

| Mold/substrate Auto-Release | Included- no special tools needed | ||

| UV exposure time | 2-3 min at 95% intensity level | ||

| Alignment capability | X, Y, Z and theta (accuracy 2 μm) | ||

Technical Specifications

| Control box operating pressure | 45 psi standard |

| Control box vacuum | < -14 psi |

| LED light source | 2" diameter, >5W |

| Filtered pressure source | 70-100 psi |

| Vacuum source | < -14 psi |

| Power | 110-220V, 50/60Hz |

| Classroom class | Class 1000 or better |

| Stage | 17" x 15.5" x 10.5", 80 lbs. |

| Touchscreen controller | 6" x 8" x 2.5", 1.5 lbs. |

| Electronic control box | 17" x 14.5" x 5.5", 11.5 lbs. |

| LED UV light source | 11" x 11" x 4.5", 7 lbs. |